Plasma Cutting Services

Get precision cuts every-time with our large-scale CNC plasma cutting services. Capable of cutting profiles up to 80mm thick (from edge) and we offer highly-versatile metal and steel cutting solutions to suit your projects needs, with clean, precision quality cutting and fast-turnarounds.

- Clean cuts up to 80mm thick.

- Medium-to-high volume production.

- ISO 9001:2015 Certified.

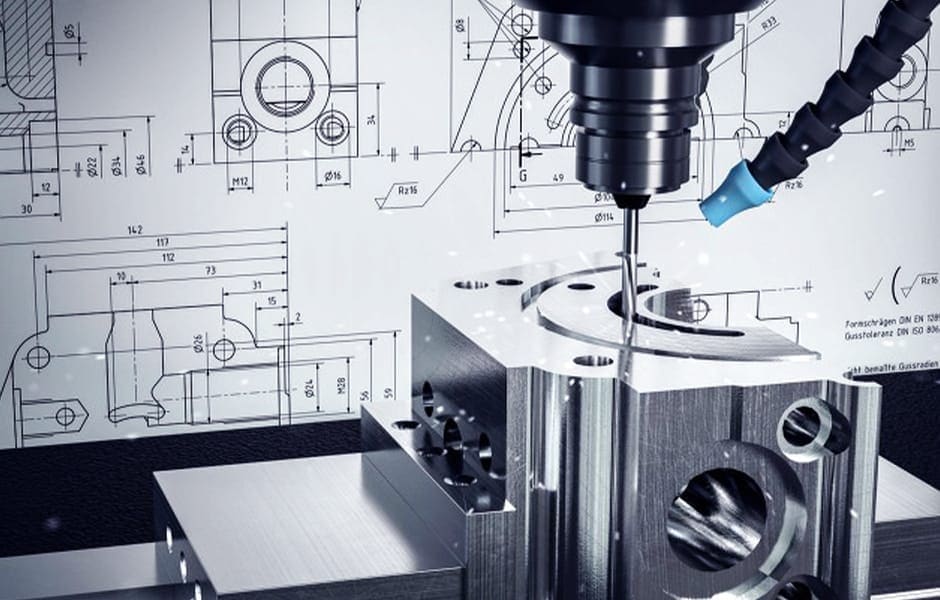

Precision CNC Plasma Cutting Capabilities

Berkeley Engineering uses the latest in plasma cutting technology to easily cut intricate shapes and complex designs. This makes plasma cutting ideal for high-volume production at scale, providing you with precision quality parts made to specification.

Got a job that requires more than just plasma cutting? We regularly factor plasma cutting into our end-to-end machining solutions, combining precision cutting with a variety of other metal fabrication services including CNC machining and CNC milling and CNC turning.

Capabilities:

Materials:

Tolerances:

Low-to-High Capacity Production Runs.

We combine the latest in technology and industry training to ensure production runs of the highest quality and standards. Our in-house CNC plasma cutting capabilities give us the advantage for mass production of precision engineered parts, guaranteeing efficient cost-savings and timely delivery for your projects needs.

- Backed by ISO 9001: 2015 certification.

- Australian manufacturing standards.

- Advanced facilities & machining capabilities.

Consistency & Quality, Gauranteed.

We take great pride in our work, ensuring each CNC plasma cut part is machined to perfection to meet your standards and expectations. Our team work with you and your drawings to maximise efficiency every step of the way, from conception to delivery.

- Capable of cuts up to 80mm thick.

- Professional design & technical support.

- 100% order satisfaction guarantee.

Our latest CNC plasma cut components.

Why choose Berkeley for your plasma cutting needs?

Quality Assurance

Our internal processes ensure that the highest quality manufacturing standards are applied to with every custom component you order. We thoroughly inspect every order throughout its production lifecycle, from conceptual drawing to finished component, following strict manufacturing guidelines that follow ISO 9001:2015 certified standards.

Flexible & Convenient

Our professional machining services are trusted by brands across Australia to work alongside their business operating needs. We understand that precision quality engineering and efficiency are essential in adhering to your deadlines, which is why we take care in every order we work on to ensure 100% satisfaction.

Competetive Pricing

We anticipate competition, especially operating in today’s modern world. As an Australian owned and operated business, we always aim to provide the best pricing & quotes for our clients, working with you to maximise efficiency and cost without any sacrifices.

IP Protection & Security

We always take your intellectual property seriously and ensure confidentiality at every stage of your order. For more information please contact us directly.

Contact Us:

We'd love to discuss your next project and how our partnered solutions can scale with your business operating needs.

Got a drawing ready to go?

Frequently Asked Questions:

How does plasma cutting work?

Plasma cutting is a widely used and highly efficient metal cutting process that employs a high-temperature plasma jet to melt and sever various types of conductive materials. This process combines gas and electrical energy to create the plasma jet.

A typical plasma cutting system is made up of a power source, an arc starting circuit, a gas supply, and a cutting torch. The power source generates a high-frequency electric current that is then transferred to the torch. The gas supply delivers a gas, such as oxygen or nitrogen, which is ionised to form the plasma jet.

The plasma jet, which can reach temperatures of up to 30,000 degrees Fahrenheit, is aimed at the workpiece, melting and removing the metal. As the plasma jet moves across the material, it produces a precise and narrow cut.

What is plasma cutting?

Plasma cutting is a versatile and efficient method used to cut through a wide range of materials, including metal and mild-steels. It involves the use of a plasma torch, which generates a high-velocity jet of ionised gas.

Plasma cutting offers several advantages over traditional cutting methods, such as oxy-fuel cutting, and produces less heat, reducing the risk of warping or distorting the material. Plasma cutting is also much faster and more precise, allowing for intricate and complex cuts to be made with ease.

What is plasma cutting used for?

Plasma cutting is used for a variety of manufacturing applications, including: metal fabrication, component manufacturing, construction, industrial maintenance & more. It’s commonly used to cut precise pieces of metal when creating complex components as part of a larger CNC machining project.

Overall, plasma cutting is a versatile and efficient method used across various industries for cutting and shaping metal materials. Its speed and ability to easily cut through materials with precision accuracy makes it a preferred choice for many applications and industries.

How quickly can you turnaround cutting orders?

Our state of the art facility include some of the latest advancements in technology, allowing us to turnaround orders more efficiently overall. We are able to turnaround orders from as fast as one (1) business day, with free shipping available on all orders. Get in touch with the team today to learn more.

What industries can benefit from CNC plasma cutting?

CNC plasma cutting is used across a wide range of industries, including agriculture, construction, mining, transportation and many more. Plasma cutting is typically part of a larger CNC machining process, providing precision cut metals for complete end-to-end metal fabrication projects.

Working with manufacturer that has the ability to handle to entire metal fabrication process, including plasma cutting, is a great way to increase production times and savings overall.

Here's what our valued customers have to say about us.

Our latest news & updates:

Precision Tolerances: The Role of Tolerances in Precision Engineering

In engineering and manufacturing, precision isn’t a luxury—it’s an expectation.…

Choosing the Right Metal for Your CNC Project: A Guide to Material Selection in Precision Engineering

The success of your project doesn’t start at the cutting…

Why Australian Manufacturers Choose Local Metal Fabrication Experts

Introduction In Australia’s evolving manufacturing landscape, businesses are under growing…

Engineering Metal Fabrication: Turning Concepts into Precision Parts

Introduction In the realm of modern engineering, the journey from…