Your Automotive Machining Partner.

Manufacturing the highest quality components for you.

Pins & Bushes

Tie Rods

Axles & Shafts

Brakes & Steering Components

Suspension Components

Hubs & Spacers

…and more

Our latest automotive parts.

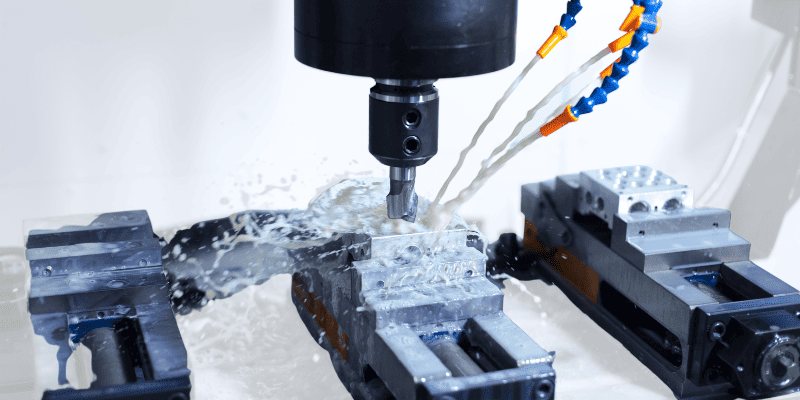

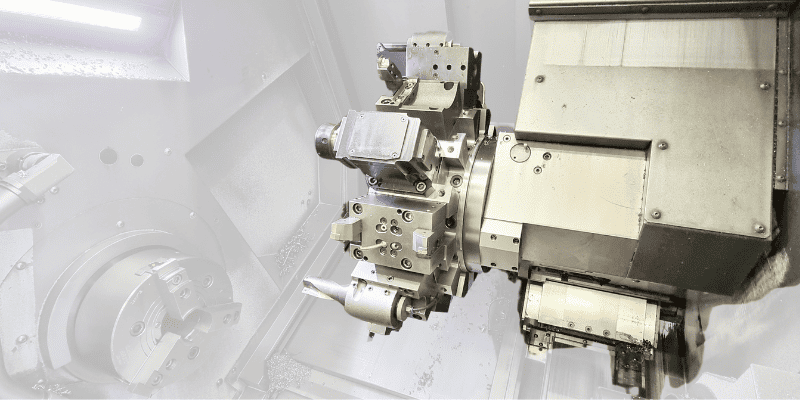

Autmotive manufacturing capabilities.

We keep the automotive industry rolling...

Berkeley Engineering is a trusted partner throughout the Australian automotive industry, providing precision crafted and durable custom machined parts used in manufacturing, repair & maintenance, performance, aftermarket parts and more.

We provide precision quality, tailor-made CNC machining solutions, made to order and to your exact specifications. From a few complex machined parts to large-scale production runs, our expert team can rapidly deliver your components at scale when you need them most.

manufacturing parts with the finest materials & expertise...

When it comes to automotives, we understand that durability, reliability and strength are essential factors to keep your business moving forward.

That’s why we only use the highest quality materials to build your precision quality parts, coupled with the most highly skilled engineering experts in the industry to get the job done right with pin-point accuracy.

...and a focus on innovation, service and quality.

At Berkeley Engineering, our commitment to our staff training, quality of standards and advancements in technology is evident in every single component that we manufacture and deliver to you.

Backed by our ISO 9001:2015 certification and manufactured to the highest Australian standards, we guarantee quality results for your custom components every time so you can focus on matters most in your business.

Let's see how we can help your business grow.

We’d love to work with you and bring your machining projects to life. Our team of engineers are able to handle projects of any scale, operating to fine machining tolerances with the utmost precision. Get in touch with our team today to see how we can help.

Automotive parts manufacturing is better with Berkeley.

Why choose Berkeley for automotive manufacturing?

Quality Assurance

Our internal processes ensure that the highest quality manufacturing standards are applied to with every custom component you order. We thoroughly inspect every order throughout its production lifecycle, from conceptual drawing to finished component, following strict manufacturing guidelines that follow ISO 9001:2015 certified standards.

Flexible & Convenient

Our professional machining services are trusted by brands across Australia to work alongside their business operating needs. We understand that precision quality engineering and efficiency are essential in adhering to your deadlines, which is why we take care in every order we work on to ensure 100% satisfaction.

Competetive Pricing

We anticipate competition, especially operating in today’s modern world. As an Australian owned and operated business, we always aim to provide the best pricing & quotes for our clients, working with you to maximise efficiency and cost without any sacrifices.

IP Protection & Security

We always take your intellectual property seriously and ensure confidentiality at every stage of your order. For more information please contact us directly.

Frequently Asked Questions:

What are some automotive parts you manufacture?

Our machine shop is capable of fine-crafting a range of automotive parts and components all made to your specifications. Some of the parts we regularly make for our clients include automotive pins, bushes, custom bolts and fasteners, tie rods, axles, shafts, brake components, steering components hubs, spacers and more.

We’d love to speak with you and learn more about your automotive machining needs. Get in touch with our team to learn more.

How does CNC machining benefit the automotive industry?

CNC machining plays a vital role in improving productivity and operations in the automotive industry. By utilising computer-controlled machines, automotive businesses can achieve high levels of precision in manufacturing agricultural equipment and components.

CNC machining also allows for greater customisation and flexibility, enabling automotive manufacturers to tailor their projects to specific tasks and requirements, improving efficiency and reducing costs overall.

How do you differ from competitors?

At Berkeley Engineering, we prioritise providing the best CNC machining services for the automotive industry as a whole.

Our focus on precision manufacturing and quality assurance has led to a reputation of trust, honesty and integrity . We’re one of the few CNC machining shops that offer a 100% satisfaction guarantee paired with free shipping Australia wide on all orders.

We understand you have a choice when it comes to finding a machinist to work with, and we understand the importance of quality and durability when it comes to sourcing a reliable machining partner.

Our latest news & updates:

The Manufacturing Benefits of Working with a CNC Machine Shop

Precision and efficiency are key factors when choosing a CNC…

CNC Machining in Various Industries: From Agriculture to Transportation

CNC machining is a highly efficient way to make custom…

The Future of Manufacturing: Exploring the Advancements with CNC Parts

CNC parts are synonymous with rapid production, meaning time is…