High Volume Australian CNC Machining Services.

Our CNC machining services.

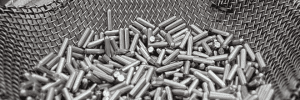

Our latest parts made from CNC Machining.

Common CNC Materials.

Stainless, Mild & Special Steels

We are capable of working with a variety of stainless steels, mild steel and special steel to suit your project needs. Some of the more common steels we use include:

Stainless Steels:

303 304 316 321 431 & more Carbon & Mild Steels:

1020 1214 1045 4140 20MnV6 EN36A Hardox Bisalloy & more Copper Alloy Metals

We’re capable of machining your components with a range of copper alloy metals, including bronze and brass, to bring your custom components to life.

Brass & Bronze:

LG2 Bronze 351 353 385 & more Copper:

Grade 1 Grade 2 Grade 3 Aluminium Metals

We work with the finest aluminium alloy metal to machine your custom components to the highest standards, working with the following material grades:

Aluminium Alloys:

2,000 5,000 6,000 Plastics

Our facilities alloy for a range of parts and components to be machined out of the finest plastic materials to suit any job. Some of the plastics we work with include:

Plastics:

Acetal Nylon Ertalon ABS & more

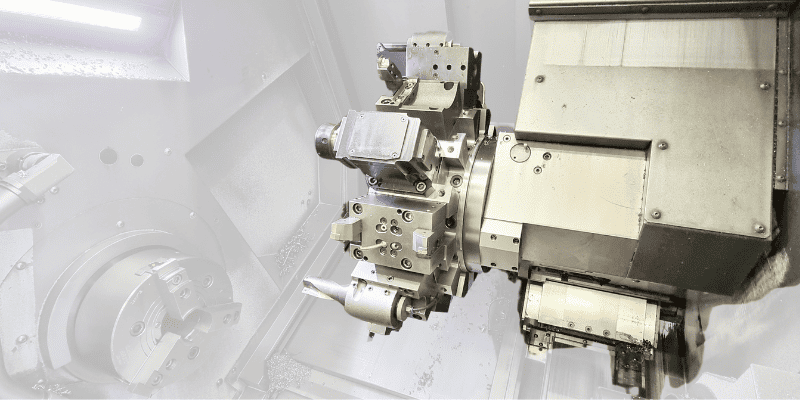

Complex CNC Machining Services at Scale.

Low to High Capacity Production Runs.

We combine the latest in technology and industry training to produce production runs to the highest standards. Our in-house capabilities give us the advantage for mass production of engineered parts, guaranteeing efficient cost-savings, control and timely delivery for your projects needs.

- Backed by ISO 9001: 2015 certification.

- Australian manufacturing standards.

- Advanced facilities & machining capabilities.

Consistency & Precision, Gauranteed.

We take great pride in our machine capabilities, ensuring each part is machined to perfection to meet your standards and manufacturing needs. Our team work with you and your drawings to maximise efficiency every step of the way, from conception to delivery.

- Tolerances from ±0.01mm.

- Professional design & technical support.

- 100% order satisfaction guarantee.

State-of-the-Art CNC Machining Services

We're Supporting Australian Industries.

Berkeley Engineering supplies a range of industries across Australia, machining CNC products to keep their business and projects moving forward. We can help your business scale too, with quick turnarounds starting from just one business day.

Frequently Asked Questions:

What is CNC Machining?

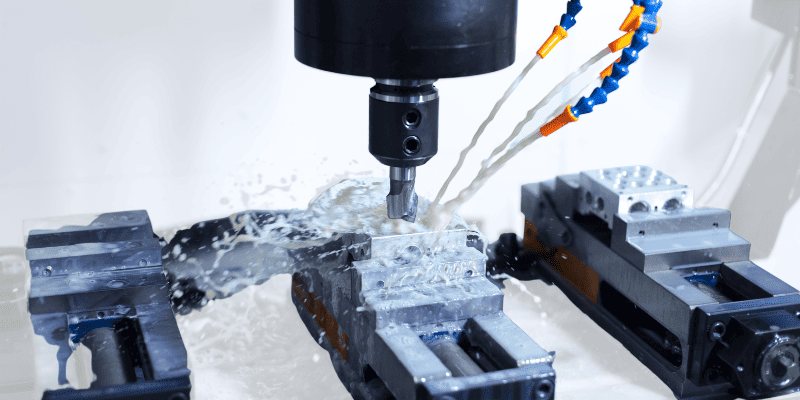

CNC machining, which stands for Computer Numerical Control machining, is a highly advanced manufacturing process that uses computer-controlled machines to shape and fabricate various parts. The technology behind CNC machining has revolutionized the manufacturing industry, allowing for increased accuracy, efficiency, and consistency in the production of complex and intricate designs.

It’s commonly referred to when talking about CNC machining milling and CNC machining turning/ lathe solutions, and offers numerous advantages, including faster production times, reduced human errors, and the ability to manufacture parts with intricate geometries. Such manufacturing techniques would be otherwise be near impossible to create manually and take much longer than any CNC manufacturing control services can process.

How does CNC Machining Work?

CNC machining is a manufacturing process that utilises computerised controls to operate and manipulate machine tools. The process begins with a CAD (computer aided design) model that specifies the desired dimensions and specifications of the final product. The CNC machine then interprets this digital design and translates it into a set of instructions, known as G-code, which guides the machine’s movements. These instructions are sent to the machine’s controller, which operates the motors and actuators to control the cutting tools. As the machine executes the commands, it removes excess material from the part, resulting in the desired shape and size.

Computer numerical control machining offers numerous advantages, including high accuracy, repeatability, and the ability to produce complex geometries. It is widely used in industries such as agriculture, automotive, and electronics for manufacturing a wide range of products.

How much does CNC Machining Cost?

CNC machining costs can vary depending on several factors. The complexity of the part being machined, the materials used, and the quantity of parts being produced can all contribute to the overall cost. Additionally, the type of machine being used, typically lathes and milling machines, and the level of precision required can also impact the price.

It is important to note that CNC machining is generally more cost-effective for larger production runs, as the initial setup costs can be spread out over a larger quantity of parts. However, for smaller production runs or one-off prototypes, the cost per part may be higher.

How to Calculate CNC Machines Time?

Calculating CNC machining time is a crucial aspect of the manufacturing process. To determine the time it takes for computer numerical control machines to complete a specific task, several factors must be considered.

The complexity of the design and the number of features to be machined play a significant role. Additionally, the material being used and the cutting tools employed can impact the machining time.

Additional metrics such as the feed rate and spindle speed settings should also be taken into account. By carefully considering these variables and using appropriate formulas or software, manufacturers can accurately calculate the time required for computer machining processes, allowing for better scheduling and resource allocation overall.

How do I reduce the cost of CNC Parts?

Reducing the costs of CNC machined parts is a crucial goal for many businesses in today’s competitive market. There are several strategies that can be implemented to achieve this objective. Firstly, optimising the design of the part can significantly reduce the amount of material used and the machining time required based on the need of the piece. This can be achieved by utilising advanced software tools to analyse and refine the design, ensuring that it is both functional and efficient.

Secondly, selecting the right materials and machining tools can also result in cost savings. Choosing materials that are readily available and affordable, while still meeting the required specifications, can help reduce material costs. Similarly, using the most appropriate machining tools for the job can improve efficiency and minimise waste.

Are CNC Machining Services essential?

CNC machining services are essential for a multitude of reasons. Firstly, thanks to the computer operations they provide precision and accuracy in the manufacturing process, ensuring that the final product meets the required specifications. This is achieved through the use of compute controlled machines that follow programmed instructions, minimising the margin for error. Additionally, CNC machining services offer a wide range of capabilities, allowing for the production of complex and intricate parts that may not be feasible with traditional machining methods.

These services enable faster production times, as the automated nature of CNC machines allows for increased efficiency and reduced human error. This is especially important in industries where speed, durability and efficiency are essential, such as agriculture or medical device manufacturing. CNC machining services additionally offer versatility, as they can work with various materials, including metals, plastics, and composites. This makes them suitable for a wide range of applications, from automotive components to electronic devices.

How do i pick the best CNC Manufacturer?

In a world where precision and efficiency matter, selecting the right CNC manufacturer can significantly impact the success of your business. From prototyping to large-scale production, the right manufacturer ensures that your designs are brought to life with utmost precision and quality.

It’s essential to identify the key factors that influence the decision-making process. These factors range from machining and technological capabilities to the manufacturer’s pre and post-sale servicing. Ensuring a reliable support system allows for a smooth process from start to finish, and makes it easier for customers knowing that their projects and machining needs are in capable hands.

We pride ourselves on having a knowledgeable team that put your CNC manufacturing needs first. From drawings to components, you’re in good hands with Berkeley Engineering.

Here's what our valued customers have to say about us.

Contact Us:

We'd love to discuss your next project and how our partnered solutions can scale with your business operating needs.

Got a drawing ready to go?

Start production today.

Our latest news & updates:

The Manufacturing Benefits of Working with a CNC Machine Shop

Precision and efficiency are key factors when choosing a CNC…

CNC Machining in Various Industries: From Agriculture to Transportation

CNC machining is a highly efficient way to make custom…

The Future of Manufacturing: Exploring the Advancements with CNC Parts

CNC parts are synonymous with rapid production, meaning time is…