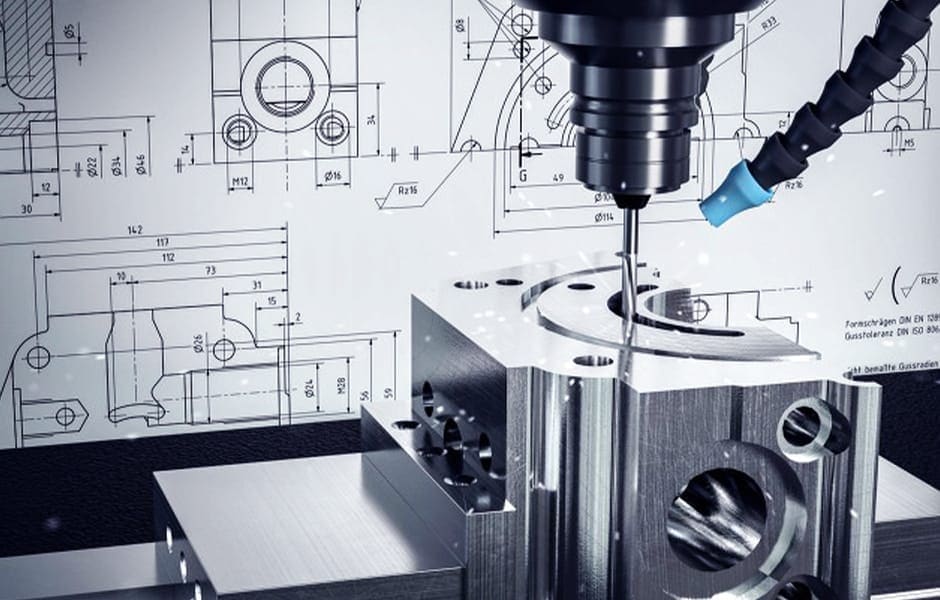

CNC Milling Services

Our precision quality custom CNC milling services will bring your parts and components to life faster. From low-to-high scale production runs, our team of in-house experts will ensure your custom CNC milling projects are completed on-time and machined to the highest specification every time.

- Fine tolerances from ± 0.01mm.

- 3 & 4-Axis CNC Milling solutions.

- ISO 9001:2015 Certified.

CNC Milling Capabilities

Berkeley Engineering offers high-quality CNC milling services capable of handling the most complex production runs with a variety of materials and finishes. From low-to-high volume runs, our CNC milling machines provide varying degrees of precision and detailing, handling any job with pin-point accuracy.

Capacity:

Materials:

Tolerances:

Multi-Axis CNC Milling

We provide advanced multi-axis custom CNC milling services for your components using a wide range of materials using the latest in machining technology. From full custom production runs using 3-axis, 4-axis CNC milling, our in-house experts can bring your complex designs to life with precision accuracy and fine tolerances of ± 0.01mm. (0.0004″)

Low-to-High Capacity Production Runs.

We combine the latest in technology and industry training to ensure production runs of the highest quality and standards. Our in-house CNC milling capabilities give us the advantage for mass production of precision engineered parts, guaranteeing efficient cost-savings and timely delivery for your projects needs.

- Backed by ISO 9001: 2015 certification.

- Australian manufacturing standards.

- Advanced facilities & milling machine capabilities.

Consistency & Quality, Gauranteed.

We take great pride in our work, ensuring each cnc milled part is machined to perfection to meet your standards and expectations. Our team work with you and your drawings to maximise efficiency every step of the way, from conception to delivery.

- Tolerances from ±0.01mm.

- Professional design & technical support.

- 100% order satisfaction guarantee.

Our latest CNC milled machine components.

Why choose Berkeley for your CNC milling?

Quality Assurance

Our internal processes ensure that the highest quality manufacturing standards are applied to with every custom component you order. We thoroughly inspect every order throughout its production lifecycle, from conceptual drawing to finished component, following strict manufacturing guidelines that follow ISO 9001:2015 certified standards.

Flexible & Convenient

Our professional production process and machine services are trusted by brands across Australia to work alongside their business requirements. We understand that precision quality engineering and machine efficiency are essential in adhering to your deadlines, which is why we take care in every order we work on to ensure 100% satisfaction.

Competetive Pricing

We anticipate competition, especially operating in today’s modern world. As an Australian owned and operated business, we always aim to provide the best pricing & quotes for our clients, working with you to maximise efficiency and cost without any sacrifices.

IP Protection & Security

We always take your intellectual property seriously and ensure confidentiality at every stage of your order. For more information please contact us directly.

Contact Us:

We'd love to discuss your next project and how our partnered solutions can scale with your business operating needs.

Got a drawing ready to go?

Frequently Asked Questions:

What is CNC Milling?

CNC milling is a precise and efficient machining process that uses computer numerical control technology to create intricate parts. It involves removing additional metal and plastic from a workpiece using rotary cutters and programmed instructions.

The CNC milling machine has multiple axes for precise control and can create a wide range of components and complex parts. This process begins with a 3D model or CAD file that is converted into instructions for the machine.

CNC milling offers high accuracy, repeatability, and the ability to work with different materials. It is commonly used in industries that require precision and efficiency, such as automotive, construction, and manufacturing.

How do CNC Milling Machines work?

CNC milling machines rely on computer software to control the movement and cutting of materials. The process starts with the operator entering the desired specifications into the computer system. Once the program is set, the machine’s cutting tools begin to shape and carve the material based on the programmed instructions. The precision and accuracy of these machines are ensured by servo motors, which control the movements of the cutting tools.

CNC milling machines excel at removing material from workpieces, whether they are made of metal, plastic, or wood, to achieve the desired shape or form. This method offers superior control and precision compared to traditional manual milling.

Thanks to their advanced technology and precise movements, CNC milling machines have become an indispensable tool in a wide range of industries, including aerospace, automotive, and electronics.

How much does CNC Milling cost?

The cost of CNC milling is determined by factors such as design complexity, material type, quantity of parts, workpiece size, and desired precision.

At Berkeley Engineering, our range of state-of-the-art CNC milling machines allow for faster production times and efficient cost-saving measures. To learn more about our process or for a free quote please contact our team today.

What industries use CNC Milling?

CNC milling is an essential manufacturing technique that caters to the diverse needs of various industries, including automotive, transportation, mining, electrical and more. The complex capabilities and applications delivered by CNC milling make it perfectly suitable for most manufacturing and machining needs, especially where complex designs/ drawings are required to bring parts and components to life.

This coupled with CNC turning and metal fabrication services provide a comprehensive end-to-end solution for brands looking to scale their projects with ease and reduced costs overall.

Is CNC Milling the same as CNC Turning?

CNC milling and CNC turning are two machining processes used in manufacturing that utilize computer numerical control (CNC) technology. However, they differ in how material is removed from the workpiece.

CNC milling involves the use of rotating cutting tools that move along multiple axes to remove material, allowing for the creation of complex shapes and contours. CNC turning uses a stationary cutting tool that moves in a linear motion while removing material as the workpiece rotates. This process is commonly used for cylindrical parts and is highly effective in creating symmetrical shapes.

Both CNC milling and CNC turning are crucial in precision machining across various industries. Manufacturers and engineers must understand the distinctions between these two processes to determine the most suitable method for their specific applications.

What types of CNC milling operations are there?

CNC milling operations encompass various techniques, including face milling, peripheral milling, pocket milling, slab milling, end milling, and helical milling. Each technique serves a specific purpose and is chosen based on factors such as desired outcome, material, and design complexity. Manufacturers can select the most suitable technique by understanding the different types of CNC milling operations available.

What type of CNC milling machines do we have?

We use a variety of state-of-the-art CNC milling machines in-house, allowing for faster machine times with highly-precise custom CNC milling operations to suit your specifications. With over 22 machines in our shop, our qualified team of engineers and machinists aim to maximise efficiency, using the latest training and industry advancements to bring your custom CNC milled component to life.

Some examples of the CNC milling machines we use include:

- 2x Doosan DNM 6700S

- Doosan DNM 500 II

- Robotic feeder(s)

Here's what our valued customers have to say about us.

Our latest news & updates:

Precision Tolerances: The Role of Tolerances in Precision Engineering

In engineering and manufacturing, precision isn’t a luxury—it’s an expectation.…

Choosing the Right Metal for Your CNC Project: A Guide to Material Selection in Precision Engineering

The success of your project doesn’t start at the cutting…

Why Australian Manufacturers Choose Local Metal Fabrication Experts

Introduction In Australia’s evolving manufacturing landscape, businesses are under growing…

Engineering Metal Fabrication: Turning Concepts into Precision Parts

Introduction In the realm of modern engineering, the journey from…