Metal Fabrication Services.

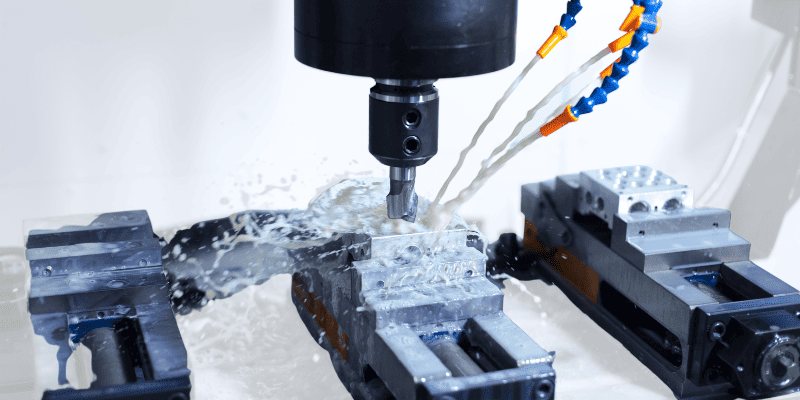

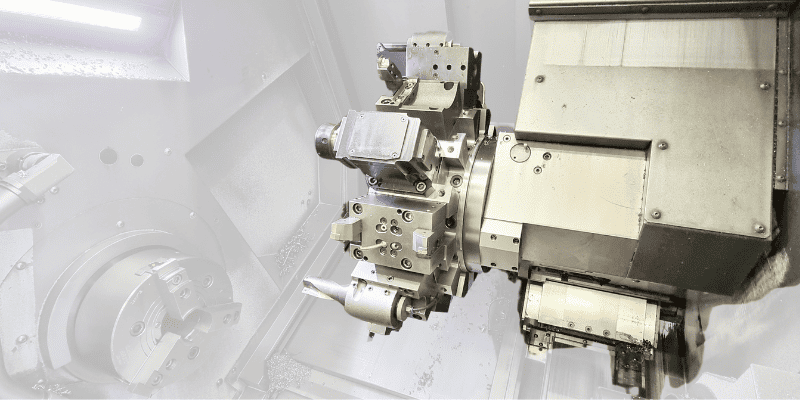

Our in-house metal fabrication services make it easier to manufacture your metal components from end-to-end. From low-to-high scale production runs, our team of in-house experts combine a range of services including CNC machining, welding, cutting and assembly to ensure your custom projects are completed on-time and to the highest specification every time.

- Complete end-to-end metal fabrication solutions.

- Medium-to-high volume production.

- ISO 9001:2015 Certified.

Your Metal Fabrication Solutions Experts

From initial design concepts to CNC machine manufacturing and assembly, we’re capable of handling your end-to-end metal fabrication needs using the highest-quality of materials with precision accuracy. Berkeley Engineering provides complete fabrication services and is trusted throughout Australia as certified experts.

Are you looking for a full-service shop to manage your metal and steel fabricating needs? We’re able to handle metal fabrication projects in varying sizes with the ability to rapidly scale & turnaround projects as required.

Capabilities:

Materials:

Our metal fabrication solutions.

Full Component Assembly

Our facilities allow for complete end-to-end metal fabrication and component assembly using a wide range of materials and the latest in machining technology. From full custom production runs using 3-axis, 4-axis, and full 5-axis CNC milling, welding, cutting and assembly, our in-house experts can bring your complex parts to life with precision accuracy and fine tolerances of ± 0.01mm. (0.004″)

If you have a project that requires machining and full assembly please get in touch with us.

Low-to-High Capacity Production Runs.

We combine the latest in technology and industry training to ensure production runs of the highest quality and standards. Our in-house metal fabrication services include welding and component assembly capabilities, giving us the advantage for mass production of precision engineered parts. This guarantees efficient cost-savings and timely delivery for all your projects needs.

- Backed by ISO 9001: 2015 certification.

- Australian manufacturing standards.

- Advanced facilities & machining capabilities.

Consistency & Quality, Gauranteed.

We take great pride in our metal fabrication work, ensuring each machined, welded and assembled part is manufactured to perfection to meet your standards and expectations. Our team work with you and your drawings to maximise efficiency every step of the way, from conception through to production, assembly and delivery.

- Tolerances from ± 0.01mm.

- Professional design & technical support.

- 100% order satisfaction guarantee.

Our latest metal components.

Why choose Berkeley for your metal fabrication services?

Quality Assurance

Our internal processes ensure that the highest quality manufacturing standards are applied to with every custom component you order. We thoroughly inspect every order throughout its production lifecycle, from conceptual drawing to finished component, following strict manufacturing guidelines that follow ISO 9001:2015 certified standards.

Flexible & Convenient

Our professional machining services are trusted by brands across Australia to work alongside their business operating needs. We understand that precision quality engineering and efficiency are essential in adhering to your deadlines, which is why we take care in every order we work on to ensure 100% satisfaction.

Competetive Pricing

We anticipate competition, especially operating in today’s modern world. As an Australian owned and operated business, we always aim to provide the best pricing & quotes for our clients, working with you to maximise efficiency and cost without any sacrifices.

IP Protection & Security

We always take your intellectual property seriously and ensure confidentiality at every stage of your order. For more information please contact us directly.

Contact Us:

We'd love to discuss your next project and how our partnered solutions can scale with your business operating needs.

Got a drawing ready to go?

Frequently Asked Questions:

What is Metal Fabrication?

Metal fabrication is the process of shaping and manipulating metal to create various products and components. It involves a wide range of techniques, including machining, cutting, welding, and assembling. It’s used in wide variety of industries, such as construction, automotive, agriculture, and manufacturing.

The process begins with the selection of the appropriate type of metal and the preparation of the raw material. The metal is then cut into the desired shape using tools like saws, lasers, or water jets. Welding is also often used to join different pieces of metal together. Finally, the fabricated metal components are all assembled and finished, which may involve processes like painting or coating. Metal fabrication requires skilled workers and specialised equipment to ensure precision and quality in the final product.

How much does metal fabrication cost?

Metal fabrication costs can vary widely depending on several factors. These factors include the type of metal being used, the complexity of the design, the quantity of the product being fabricated, and the location of the fabrication shop. In general, stainless steel tends to be more expensive than other metals due to its durability and corrosion resistance.

The complexity of the design also plays a role in determining the cost, as intricate designs require more time and skill to fabricate. Additionally, larger quantities of the product being fabricated can result in lower costs per unit.

Can you handle my products end-to-end fabrication?

Of course we can. Berkeley Engineering provides complete end-to-end manufacturing for all your CNC machining services, including milling, turning, cutting, welding and assembly. We work with customers from initial drawings and design concepts through to large scale manufacturing, production and delivery.

To speak to a technical expert regarding your metal fabrication needs, give us a call or contact us online and one of our technical managers will be in touch as soon as possible.

What process is involved in metal fabrication?

Metal fabrication involves a complex and intricate process that transforms raw metal into finished products. This multifaceted process typically includes several steps such as cutting, machining, welding, and assembling.

The end result is a high-quality product that meets your production requirements and specifications. Metal fabrication is a precise and intricate process that requires skilled craftsmanship and attention to detail at every stage.

What industries benefit from fabricated metal parts?

Several industries benefit greatly from fabricated metal components, including (but not limited to) agriculture, electrical, mining, and transportation. Metal fabrication plays a significant role in the ongoing growth and development of these industries, enhancing efficiency and durability to maximise performance across the board.

Here's what our valued customers have to say about us.

Our latest news & updates:

The Manufacturing Benefits of Working with a CNC Machine Shop

Precision and efficiency are key factors when choosing a CNC…

CNC Machining in Various Industries: From Agriculture to Transportation

CNC machining is a highly efficient way to make custom…

The Future of Manufacturing: Exploring the Advancements with CNC Parts

CNC parts are synonymous with rapid production, meaning time is…