Your new CNC machining solutions partner.

When you work with Berkeley Engineering, you'll be assigned a dedicated account manager to help guide you through the process. We'll share insight and expertise from our in-house engineers and expert machinists to best produce your drawings to pin-point accuracy and to your projects' deadline and budget.

Have an urgent job that needs machining? We can handle that for you. We have the ability to scale production to fit with large scale production runs and expedited orders of any size. With over 23+ machines in our shop, our dedicated team will work with you to ensure you get what you need every time with free delivery in as fast as 1-business day. That's why it's better with Berkeley.

Ready to start your next project with Berkeley?

Quality Assurance

Our internal processes ensure that the highest quality manufacturing standards are applied to with every custom component you order. We thoroughly inspect every order throughout its production lifecycle, from conceptual drawing to finished component, following strict manufacturing guidelines that follow ISO 9001:2015 certified standards.

Flexible & Convenient

Our professional machining services are trusted by brands across Australia to work alongside their business operating needs. We understand that precision quality engineering and efficiency are essential in adhering to your deadlines, which is why we take care in every order we work on to ensure 100% satisfaction.

Competetive Pricing

We anticipate competition, especially operating in today’s modern world. As an Australian owned and operated business, we always aim to provide the best pricing & quotes for our clients, working with you to maximise efficiency and cost without any sacrifices.

IP Protection & Security

We always take your intellectual property seriously and ensure confidentiality at every stage of your order. For more information please contact us directly.

Contact Us:

We'd love to discuss your next project and how our partnered solutions can scale with your business operating needs.

Got a drawing ready to go?

Frequently Asked Questions:

What's the finest tolerance you can work to?

Our machines are capable of high precision manufacturing, handling some of the most complex parts and components at varying sizes. Tolerance capability highly depends on the nature of the job, the material used and the machining processes involved.

In most scenarios we can hold ± 0.01mm tolerances, however our team of engineers and experts can recommend the best approach to ensure capability. To learn more if we can help with your precision manufacturing needs please contact our team.

Do you provide quotes for custom jobs?

CNC machining can vary in costs depending largely on the manufacturing requirements and complexity of the job. The cost of materials, setup time, run time, quantity & tooling requirements are also all factors that must be taken into consideration when quoting components.

Every product we manufacture is unique to the clients we service, and is quoted individually based on the complexity of the job. We do however obtain several machines and automated facilities in-house to help reduce costs overall, plus don’t forget that every order we quote includes free shipping from our shop to your door.

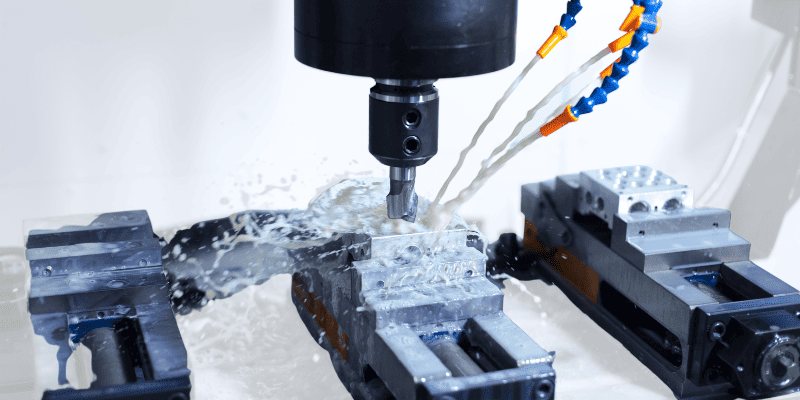

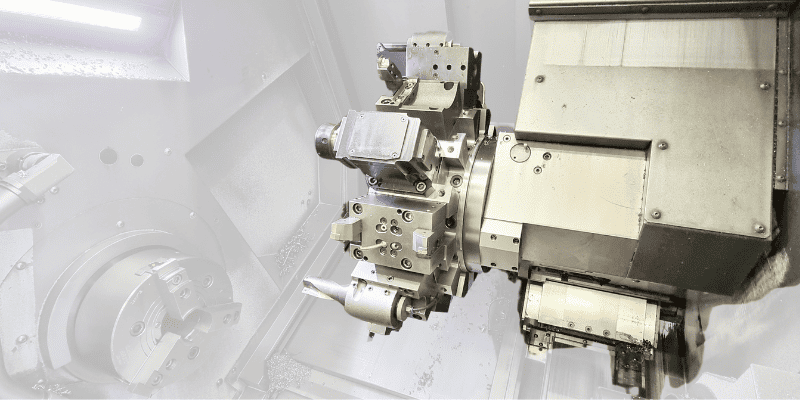

What machining & metal fabrication services do you provide?

We’re experts in a wide range of complete end-to-end metal fabrication services, from plasma cutting through to CNC milling and CNC turning and welding/ assembly. With over 21+ machines on premises, our team of experts can help bring your custom components and large scale projects to life with a focus on efficiency, durability and quality precision.

Contact our team today to learn more about how we can help with your custom machining needs.

How can I reduce costs of CNC machined parts?

You can lower your machining costs by increasing efficiency and feed rates during the production of your components. The length of time required for a project, the machine(s) used, material costs and tooling requirements all contribute to the overall production costs.

It is also possible to automate some machining processes for simpler machining jobs, utilising bar feeders and robotics to aid in reducing costs. This depends on the unique component being machined and the ability to automate certain processes.

Here's what our valued customers have to say about us.

Our latest news & updates:

CNC Machining Service for Medical Devices: Meeting Industry Standards

The manufacturing of medical devices requires extreme precision CNC machining and adherence…

CNC Machining Service: Precision and Safety in Plasma Cutting Electrical Applications

In the world of electrical applications, precision is paramount. The CNC…

CNC Machining Service in the Agriculture Industry: Enhancing Equipment Precision

In today’s competitive agricultural landscape, machinery plays a vital role…

CNC Machining Service: Metal Fabrication in Construction – Building the Future

Introduction Metal fabrication has long been a cornerstone of modern…