The Future of CNC Machining: Trends and Innovations

CNC machining has revolutionised the manufacturing industry and is poised to continue to shape the future of production. With its precision and efficiency, CNC machines have become an integral part of various sectors, including automotive, agriculture, and transportation; and the future of CNC machining holds even more promising advancements in this field. Innovations such as artificial intelligence and machine learning are being incorporated into CNC systems, enhancing their capabilities and allowing for more complex designs and intricate machining processes.

The integration of Internet of Things (IoT) technology, otherwise known as Web 3.0, enables real-time monitoring and remote control of CNC machines, optimising productivity and reducing downtime. Additionally, advancements in 3D printing and additive manufacturing are expanding the possibilities of CNC machining, enabling the production of intricate and customised parts with ease. As the demand for high-quality, precise components continues to rise, CNC machining will continue to evolve and play a crucial role in shaping the future of manufacturing.

In this article, we’ll asses 6 different ways that CNC machining services will likely evolve over the years to better suit customers needs and increase efficiencies overall.

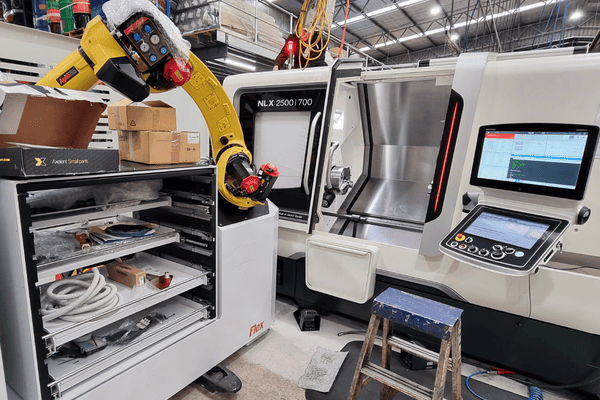

1. Increased Automation: With the continuous advancement of technology, it is anticipated that CNC machining will witness a rise in automation. This implies that robots and machines will undertake a greater number of tasks, thereby minimising the requirement for human involvement. Consequently, efficiency will be enhanced, and the likelihood of human error will be diminished.

At Berkeley Engineering, we’ve invested heavily in automated CNC machining technology. We regularly use bar-feeders for majority our turning machines, and as of September 2023 have introduced a new Agile Flex 35D robotic arm to aid machine loading and handle larger orders. As a result, these automations allow for increased efficiencies across the board when it comes to time-saving and cost reductions.

2. Integration of Artificial Intelligence: Artificial intelligence (AI) has the potential to transform CNC machining even further. AI algorithms can analyse vast amounts of data, optimise the machining processes, and make predictive maintenance recommendations. This will eventually lead to improved accuracy, faster production times, and cost savings which are passed on to clients.

3. 3D Printing and CNC Machining Integration: 3D printing has gained significant traction in recent years, allowing for rapid and cost-effective prototyping. In the future, we can expect to see increased integration between 3D printing and CNC machining. This combination of machining practices will enable the production of complex parts and components with a higher level of precision.

4. Advanced Materials and Finishes: CNC machining services have traditionally been used with metals and plastics. However, as new materials and finishes are being developed, CNC machining will expand its capabilities. This could eventually include machining materials such as ceramics, composites, and even biodegradable materials. These advancements will open up new possibilities for various industries, including aerospace, healthcare, and automotive.

5. Improved Sustainability: With the growing concern for environmental sustainability, CNC machining will continue to evolve to reduce its impact. This may include the development of more energy-efficient machines, the use of eco-friendly materials, and the implementation of recycling programs for waste materials.

We take great pride in our recycling program at Berkeley Engineering, working in tandem with our material suppliers to ensure all scrap is recycled where possible.

6. Remote Monitoring and Control: As connectivity becomes more prevalent, remote monitoring and control of CNC machines will become more common. This will allow manufacturers to monitor production processes in real-time, make adjustments remotely, and improve overall efficiency. It will also enable manufacturers to provide remote technical support, reducing downtime and increasing productivity.

In Conclusion

Machining remains an essential component of the manufacturing industry due to the continuous progress in automation, artificial intelligence, material capabilities, and sustainability practices. The implementation of new technology will result in accelerated manufacturing processes, improved accuracy, and enhanced productivity; ultimately leading to the development of innovative and cost-efficient products. At Berkeley Engineering, we’re excited to be at the forefront of Australian CNC machining advancements.

Who are we?

Berkeley Engineering has a rich history of producing high-quality components since 1931. Our CNC machining operations in Australia offer a comprehensive range of services, including CNC turning, metal fabrication, plasma cutting and more. We are dedicated to delivering custom components of the finest quality for your projects. Whether you require low or high volume production, our manufacturing services are cost-effective and efficient, with turnaround times as fast as one business day.

Contact Us:

We'd love to discuss your next project and how our partnered solutions can scale with your business operating needs.