Precision Tolerances: The Role of Tolerances in Precision Engineering

In engineering and manufacturing, precision isn’t a luxury—it’s an expectation. Whether you’re machining aerospace components, producing medical devices, or building parts for critical infrastructure, tight tolerances are what stand between reliable performance and costly failure.

Tolerances define the maximum and minimum sizes a part can be while still functioning as intended. They’re the allowable variation that ensures mating parts fit together seamlessly and perform under load, vibration, and stress. When tolerances aren’t right, even the most advanced machining processes can produce components that fail inspection or, worse, fail in the field.

Today’s industries demand more than just parts that “look right.” They require dimensional accuracy, verified with precise measurement tools and controlled through geometric dimensioning and tolerancing (GD&T). At Berkeley Engineering, we specialise in achieving tight CNC machining tolerances that meet or exceed industry standards—every time.

In this article, we’ll break down why tolerances matter, how they’re measured and maintained, and what sets high-precision machining apart. If you’ve ever wondered how the smallest details can significantly affect quality, reliability, and safety, you’re in the right place.

Key Takeaways

- Tight tolerances ensure that parts fit correctly, function as designed, and meet engineering requirements without costly rework.

- CNC machining tolerances provide repeatability and consistency even in high-volume manufacturing.

- Standards like GD&T and ISO tolerance requirements guide how tolerances are specified, measured, and verified.

- Choosing the right material condition, surface finish, and measurement tools is essential to achieving the desired tolerances.

- Berkeley Engineering uses advanced machining methods and rigorous QA to deliver high-quality components that keep your operations running smoothly.

Summary Table

| Factor | Impact on Precision Tolerances |

|---|---|

| Dimensional Accuracy | Ensures parts meet specified dimensions and fit within the acceptable range |

| Surface Roughness Considerations | Impacts sealing, friction, and long-term wear |

| GD&T and Standard Tolerances | Provide clear guidelines for allowable variation and inspection criteria |

| Material Properties | Affect machining stability and final tolerance |

| Advanced Measurement Tools | Verify that upper and lower limits are met reliably |

What Are Precision Tolerances?

Precision tolerances define how much a dimension can deviate from its nominal value without affecting a part’s function or fit. In simple terms, they are the acceptable range of variation between the maximum and minimum sizes a feature can have. Even small differences can significantly affect whether mating parts assemble correctly, seal properly, or perform under load.

Engineering tolerances can be expressed in different ways, including:

- Limit tolerances: Specify an upper limit and lower limit between which a dimension must fall.

- Bilateral tolerances: Allow variation in both directions (e.g., ±0.02mm).

- Unilateral tolerances: Allow variation only in one direction (e.g., +0.01/-0.00mm).

- Geometric dimensioning and tolerancing (GD&T): Adds controls for form, orientation, and position—especially important for complex geometry or cylindrical shapes.

These tolerances aren’t arbitrary—they’re based on:

- Functional requirements: What the part must do.

- Material properties: Which metals or composites are used.

- Manufacturing process capability: What the CNC machining process can reliably achieve.

- Industry standards: Requirements like ISO, ASME, or aerospace guidelines.

For example, high precision machining of aerospace components or medical devices often demands tolerances within a few microns, verified with advanced measurement tools such as CMMs or laser scanners. In contrast, less critical parts might allow broader standard tolerance ranges.

At Berkeley Engineering, we work closely with clients to define the desired tolerances and ensure that every finished part is within spec. By understanding what tolerances are and how they’re applied, you can better plan for cost, quality, and performance.

CNC Machining and Tight Tolerances

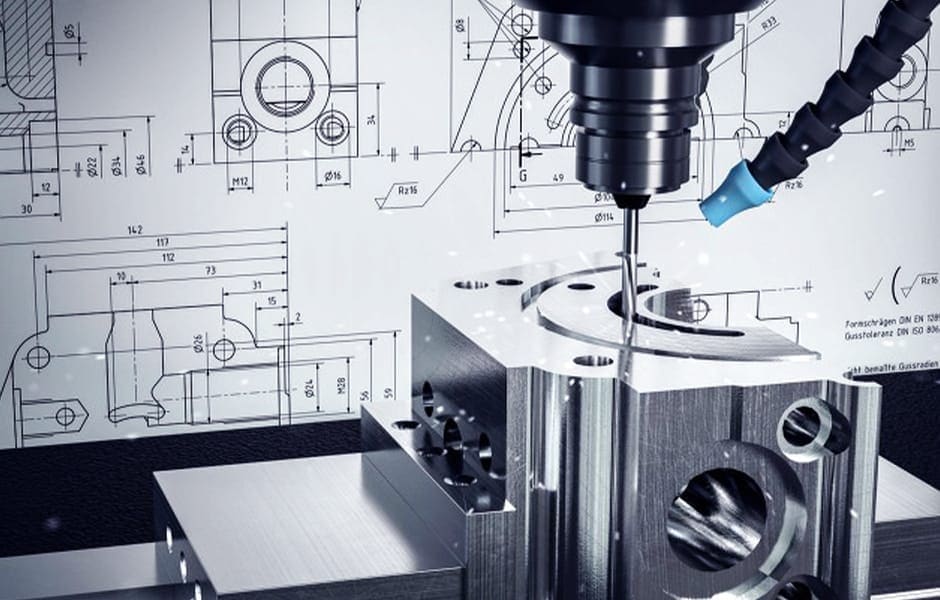

CNC machining is the backbone of achieving tight tolerances in modern manufacturing. Unlike manual processes, CNC machining uses computer-guided controls to position cutting tools with extreme accuracy—often within a fraction of a millimetre. This capability makes it possible to produce parts with dimensional accuracy that meets the most demanding tolerance requirements.

How do CNC machining tolerances work?

The process starts with a 3D CAD model that specifies the nominal dimension, along with any upper and lower limits or geometric dimensioning and tolerancing (GD&T) requirements. The CNC machine then interprets this data to produce each feature to the exact specification, whether it’s a bore diameter, a complex contour, or an angular dimension.

Advanced CNC equipment—including multi-axis machining centres, screw machining systems, and high-precision milling machines—can hold tolerances as tight as ±0.01mm depending on:

- The material condition (e.g., aluminium vs. hardened steel)

- Machining methods used (turning, milling, grinding)

- The stability of fixturing and tooling

- The capability of measurement tools for verification

When producing CNC machined parts, Berkeley Engineering also considers factors like surface roughness considerations, allowable variation, and profile tolerances to ensure that every dimension is not only accurate but consistent across batches.

Why does this matter?

In many industries—especially aerospace, defence, and medical—standardised tolerances alone aren’t enough. Components need to achieve tighter CNC machining tolerances to guarantee:

- Reliable fit between mating parts

- Proper clearances and maximum material condition

- Performance under thermal and mechanical stress

By combining advanced machinery, skilled operators, and rigorous quality systems, CNC machining bridges the gap between design intent and finished part performance.

Geometric Dimensioning and Tolerancing (GD&T)

While basic limit tolerances define acceptable size ranges, Geometric Dimensioning and Tolerancing (GD&T) goes further—specifying the shape, orientation, and exact placement of features. It’s the language of precision that ensures parts fit and function exactly as intended, especially when dealing with complex geometry and assemblies with multiple mating parts.

What does GD&T include?

GD&T uses symbols and datums to control characteristics such as:

- Form (flatness, straightness, cylindricity)

- Orientation (parallelism, perpendicularity, angularity)

- Location (position, concentricity, symmetry)

- Runout (how much a feature deviates when rotated)

For example, rather than simply specifying a hole’s nominal dimension and allowable variation, GD&T defines the exact profile tolerance and orientation relative to a reference datum—reducing ambiguity and avoiding guesswork during inspection.

Why is GD&T important?

In high-stakes manufacturing—think aerospace components or medical devices—tight tolerances alone don’t guarantee function. You also need:

- True position so parts align perfectly

- Control over surface roughness considerations

- Verification of upper and lower limits across every dimension

GD&T also helps manage tolerance stack-up in assemblies. By controlling each feature’s relationship to others, you prevent cumulative errors that could impact performance or safety.

How does Berkeley Engineering apply GD&T?

Our team is experienced in interpreting and applying GD&T to ensure that high precision machining delivers exactly what your design demands. Using advanced measurement tools like CMMs, we verify:

- Dimensional accuracy

- Profile tolerances

- Conformance to specified tolerances

This meticulous approach means every CNC machined part is ready to perform—no surprises, no rework, and no compromise.

Why Tight Tolerances Matter

Tight tolerances are more than a box to tick—they’re the foundation of product reliability, performance, and safety. In precision engineering, even a small deviation beyond the acceptable range can lead to failures that significantly affect how a part operates.

Here’s why they matter:

Performance & Functionality

If a shaft doesn’t meet its specified tolerance, it could create excessive play or friction. That means faster wear, higher operating temperatures, and reduced efficiency. In applications like aerospace components or medical devices, these issues aren’t just inconvenient—they can be catastrophic.

Fit and Assembly

Tolerances ensure parts slot together as intended. A component out of spec by just a fraction can prevent assemblies from seating correctly, create leaks in a seal, or damage mating parts. Precision machining keeps everything within the upper and lower limits, ensuring a reliable fit.

Consistency & Repeatability

Production environments rely on predictable quality. By controlling dimensional accuracy and surface roughness, tight tolerances mean every part meets the same standard—batch after batch.

Cost Control & Efficiency

While achieving high precision machining may require more advanced processes and QA, it also reduces the hidden costs of rework, scrap, and downtime. Investing in tighter tolerances upfront pays dividends over a component’s lifecycle.

Industry Compliance

From ISO standards to customer-specific requirements, most sectors have strict tolerance expectations. Failing to meet them can mean rejected parts, delayed projects, or lost contracts.

At Berkeley Engineering, we understand these stakes. Our commitment to tight tolerances isn’t about over-engineering—it’s about ensuring every finished part performs exactly as it should, for as long as it should.

Challenges in Achieving Tight Tolerances

Achieving tight tolerances isn’t as simple as setting a machine and pressing start. It demands the right combination of machining methods, tools, and expertise to manage the many variables that can impact dimensional accuracy.

Here are some of the biggest challenges:

Material Properties

Different materials behave differently under cutting forces and heat. Aluminium may expand slightly, while hardened steel can create vibration and tool wear. Maintaining a specified tolerance means accounting for these properties before and during machining.

Surface Roughness Considerations

Even if dimensions are within spec, surface finish matters. Roughness can affect sealing, friction, and wear—especially in mating parts. Balancing the need for tight tolerances with smooth finishes often requires secondary processes like grinding or polishing.

Complex Geometry

Parts with cylindrical shapes, thin walls, or multiple critical dimensions can be more difficult to hold within the allowable variation. Features may distort during machining or as material is removed, requiring meticulous planning and fixturing.

Measurement and Verification

It’s one thing to machine a part—it’s another to prove it’s within the upper and lower limits. Verifying limit tolerances demands high-precision measurement tools, skilled operators, and consistent processes. Even environmental factors like temperature can influence readings.

Cost and Time Pressure

Tighter tolerances can increase machining time and require specialised tooling or advanced machinery. Operations managers must weigh the benefits of tighter specs against production costs and lead times.

At Berkeley Engineering, we tackle these challenges with experience and a proactive mindset. We collaborate with clients to define the right tolerance—balancing function, manufacturability, and budget—so you get the performance you need without unnecessary complexity.

How Berkeley Engineering Delivers Consistency

At Berkeley Engineering, delivering components that meet tight tolerances isn’t an aspiration—it’s a standard. Our approach combines the right technology, people, and processes to ensure every CNC machined part is made precisely to spec.

Advanced Machinery and Processes

We invest in state-of-the-art high precision machining centres capable of producing parts with tolerances as tight as ±0.01mm. From screw machining to multi-axis milling, our shop floor is equipped to handle everything from simple brackets to parts with complex geometry.

Standardised Tolerances and QA Systems

Our work is governed by established standard tolerance frameworks and industry requirements, including ISO 9001:2015. Every part undergoes in-process checks and final inspections using measurement tools such as coordinate measuring machines (CMMs), micrometres, and surface roughness testers. This ensures no detail slips through.

Experienced Team

Our machinists and engineers understand how small deviations can significantly affect the performance of mating parts. Their expertise allows us to anticipate issues like material distortion, heat expansion, or tolerance stack-up and correct them before they impact your project.

Collaborative Approach

We work closely with clients to understand your desired tolerances, function, and budget. If you’re unsure how tight tolerances will impact cost or lead time, we’ll provide clear guidance so you can make informed decisions.

Documented Traceability

For critical applications—especially in aerospace components or medical devices—we maintain full records of every step in the process. From initial setup to final inspection, you can be confident every part meets your specifications.

This commitment to precision is how Berkeley Engineering helps manufacturers, builders, and innovators achieve reliable performance, project after project.

Final Thoughts

Across modern manufacturing, tight tolerances are no longer optional—they’re essential. Whether you’re producing a single prototype or running high-volume production, precision is what separates a part that simply looks the part from one that performs under pressure, day after day.

At Berkeley Engineering, we see tolerances as more than numbers on a drawing. They’re the foundation of trust between your design and our manufacturing capability. They’re what ensures each component fits seamlessly, performs reliably, and delivers value over its entire lifecycle. When you work with our team, you can BE Assured that every detail—from material selection to measurement verification—is managed with care, experience, and commitment.

If your next project demands uncompromising accuracy, or if you’d like to better understand how tolerances affect your parts, we’re here to help. Because in precision engineering, it’s the smallest margins that make the biggest difference.

FAQs Answered:

1. What are engineering tolerances and why are they important?

Engineering tolerances define the permissible limits of variation in a physical dimension or measurement. They ensure that even with slight deviations, parts will fit, function, and perform as expected. Tolerances are crucial for ensuring the proper fit, function, and performance of assembled products.

2. What is Geometric Dimensioning and Tolerancing (GD&T)?

Geometric Dimensioning and Tolerancing (GD&T) is a system for defining and communicating engineering tolerances via a symbolic language on engineering drawings and computer-generated 3D models. GD&T is used to define the nominal geometry of parts and assemblies, the allowable variation in size, form, orientation, and location of individual features, ensuring that parts fit and function properly.

3. How do tight tolerances impact manufacturing costs?

Tight tolerances can increase manufacturing costs due to the need for more precise machinery, longer production times, and increased quality control measures. However, they are essential for parts that require high precision to function correctly, such as in aerospace or medical devices.

4. What are common challenges in achieving tight tolerances?

Achieving tight tolerances can be challenging due to factors like material properties, machine precision, and environmental conditions. Materials may expand or contract with temperature changes, and machines must be calibrated correctly to maintain precision. Additionally, complex part geometries can make it difficult to maintain consistent tolerances throughout the manufacturing process.

5. How does GD&T improve communication in manufacturing?

GD&T provides a standardized language that clearly communicates the design intent of parts, reducing ambiguity and errors in manufacturing. By specifying allowable variations in form, orientation, and location, GD&T ensures that all stakeholders have a clear understanding of the requirements, leading to improved quality and consistency in production.

Who are we?

Berkeley Engineering has a rich history of producing high-quality components since 1931. Our CNC machining operations in Australia offer a comprehensive range of services, including CNC turning, metal fabrication, plasma cutting and more. We are dedicated to delivering custom components of the finest quality for your projects. Whether you require low or high volume production, our manufacturing services are cost-effective and efficient, with turnaround times as fast as one business day.

Contact Us:

We'd love to discuss your next project and how our partnered solutions can scale with your business operating needs.