Enhancing Transportation Reliability with CNC Machining

Introduction

Efficient and reliable transportation systems depend heavily on components crafted with absolute precision. In an industry where even minor defects can compromise safety and performance, CNC (Computer Numerical Control) machining is indispensable. By ensuring unmatched accuracy and consistency, CNC machining supports the production of critical components across Australia’s transportation sector. At Berkeley Engineering, we specialise in delivering CNC machined components that guarantee efficiency, safety, and reliability, so Australian transport businesses can BE Assured of their operations.

Key Takeaways

- CNC machining provides precision-engineered components crucial for transport safety and efficiency.

- Precise material selection and advanced machining techniques enhance component performance.

- CNC machining reduces production errors and ensures consistently high-quality output.

Summary Table

| Feature | Benefits to Transportation Industry |

| Precision Manufacturing | Ensures accurate fit and optimal performance |

| Material Versatility | Tailored components for diverse conditions |

| Enhanced Safety | Reduces risk through accurate component design |

| Improved Reliability | Reduces downtime and maintenance costs |

CNC Machining: Revolutionising Transportation Components

CNC machining is critical to creating precise transportation components, from automotive parts to rail and aerospace applications. Using computer-controlled machinery, it delivers consistency and accuracy impossible with manual methods, achieving tolerances as precise as ±0.01mm. Such precision ensures critical components function flawlessly in demanding transportation environments.

Berkeley Engineering leverages advanced CNC machining technology, enabling Australian transportation businesses to achieve superior reliability and operational efficiency.

Applications in the Transportation Sector

1. Automotive Industry

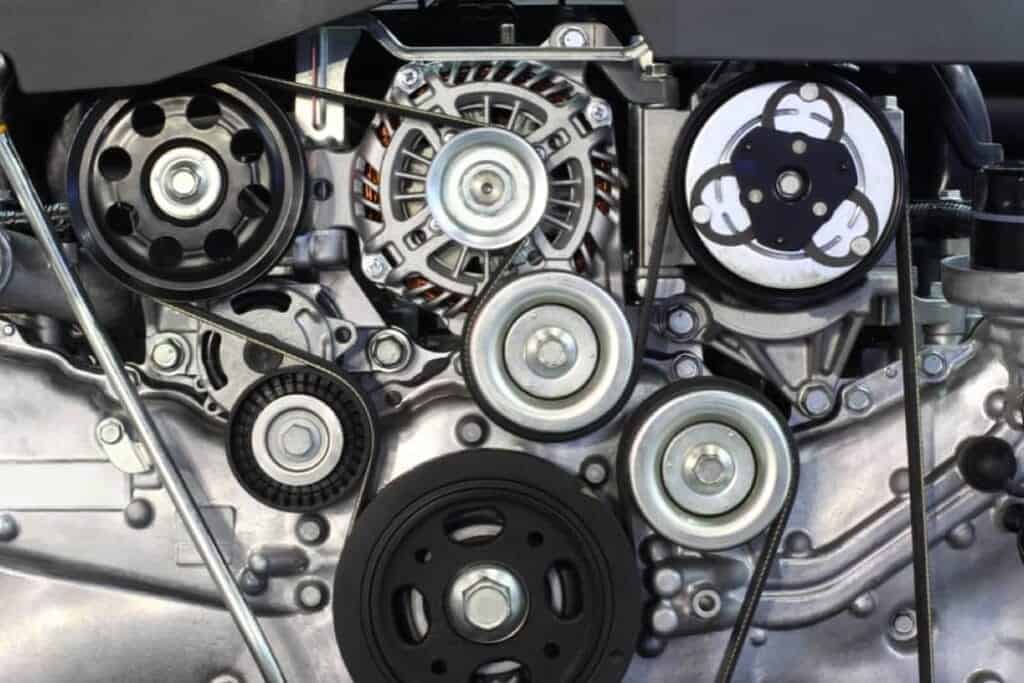

- Engine and transmission components

- Brake system parts

- Steering and suspension components

2. Rail Industry

- Wheel assemblies

- Structural and chassis components

- Precision couplings and linkages

3. Aerospace

- Lightweight structural components

- Critical engine components

- Precision instrumentation housings

Material Selection for Transportation Excellence

Proper material selection is critical to CNC machining, impacting durability, weight, safety, and overall performance. Berkeley Engineering precisely machines an extensive range of materials to suit transport-specific requirements:

- Aluminium Alloys: Lightweight, durable, corrosion-resistant

- Stainless Steel: Exceptional strength, corrosion resistance, ideal for harsh environments

- Titanium: Ideal for strength-to-weight ratio, essential for aerospace and high-performance automotive applications

- Plastics and Composites: Lightweight materials offering exceptional durability and versatility

The Berkeley Engineering Advantage: BE Assured of Precision

With over 90 years of precision engineering experience, Berkeley Engineering is a trusted partner to Australia’s transportation sector. Our CNC machining services deliver:

- Exceptional Precision: Tight tolerance capabilities (±0.01mm)

- Reliable Quality: ISO 9001-certified processes and rigorous quality inspections

- Timely Delivery: Commitment to meeting deadlines to ensure minimal downtime

Real-World Success Stories

Automotive Precision

An Australian automotive company required precisely engineered gearbox components. Berkeley Engineering delivered CNC-machined parts meeting exact specifications, significantly enhancing gearbox reliability and performance.

Rail Industry Reliability

A rail transport client sought reliable, high-strength coupling components. Berkeley Engineering produced precision CNC-machined parts that reduced maintenance frequency and improved operational reliability.

FAQs Answered:

Q: What precision can Berkeley Engineering achieve with CNC machining?

A: We regularly hit tolerances as tight as ±0.01mm—because when it comes to transport components, near enough just doesn’t cut it. It’s about reliability, every time.

Q: Which materials are best suited for transportation components?

A: We machine aluminium alloys, stainless steel, titanium, and high-strength composites—chosen based on your specific performance, weight, and environmental demands.

Q: Why is CNC machining important for transport safety?

A: Precision-built parts mean fewer failures and safer vehicles. CNC machining ensures every component meets spec, performs consistently, and holds up under real-world conditions.

Q: Can Berkeley Engineering handle large volume transport component production?

A: Absolutely. Whether you need a one-off prototype or full-scale production, we’ve got the tech and capacity to deliver—fast, accurate, and on time.

Q: Does Berkeley Engineering provide customised transportation solutions?

A: 100%. We work closely with you to design and machine parts that meet your exact application requirements—no compromises, no shortcuts.Contact Berkeley Engineering Today

Ready to enhance the reliability and efficiency of your transportation components? Contact Berkeley Engineering and BE Assured of quality, precision, and reliability.

Who are we?

Berkeley Engineering has a rich history of producing high-quality components since 1931. Our CNC machining operations in Australia offer a comprehensive range of services, including CNC turning, metal fabrication, plasma cutting and more. We are dedicated to delivering custom components of the finest quality for your projects. Whether you require low or high volume production, our manufacturing services are cost-effective and efficient, with turnaround times as fast as one business day.

Contact Us:

We'd love to discuss your next project and how our partnered solutions can scale with your business operating needs.