CNC Machining for Mining Equipment: Precision in Harsh Environments

Introduction

Mining is an industry known for harsh environments, intense operational demands, and extreme durability requirements. Precision, reliability, and robustness of equipment can significantly impact safety, productivity, and overall operational efficiency. CNC (Computer Numerical Control) machining has emerged as a critical solution for manufacturing precision components that withstand these harsh conditions. At Berkeley Engineering, our CNC capabilities provide exceptional precision, enabling Australian mining companies to BE Assured of quality, reliability, and durability in every component produced.

Key Takeaways:

- CNC machining ensures tight tolerances and reliable component durability for harsh mining environments.

- Material choice and machining precision directly influence equipment longevity and performance.

- CNC machining delivers consistent quality for high-volume or custom mining equipment components.

Summary Table

| Feature | Benefits in Mining Environments |

| Precision Machining | Tight tolerances, reliable performance |

| Robust Materials | Resistance to wear, corrosion, and harsh environments |

| Customisation | Tailored components to exact operational needs |

| Reliability | Reduced downtime, increased equipment lifespan |

CNC Machining for Mining Equipment: An Overview

CNC machining involves the use of computer-controlled machinery to fabricate metal components precisely to specification. In mining operations, the ability to produce parts with exact tolerances ensures optimal equipment functionality and safety. With tolerances achievable down to ±0.01mm, CNC machining delivers exceptional accuracy for critical components.

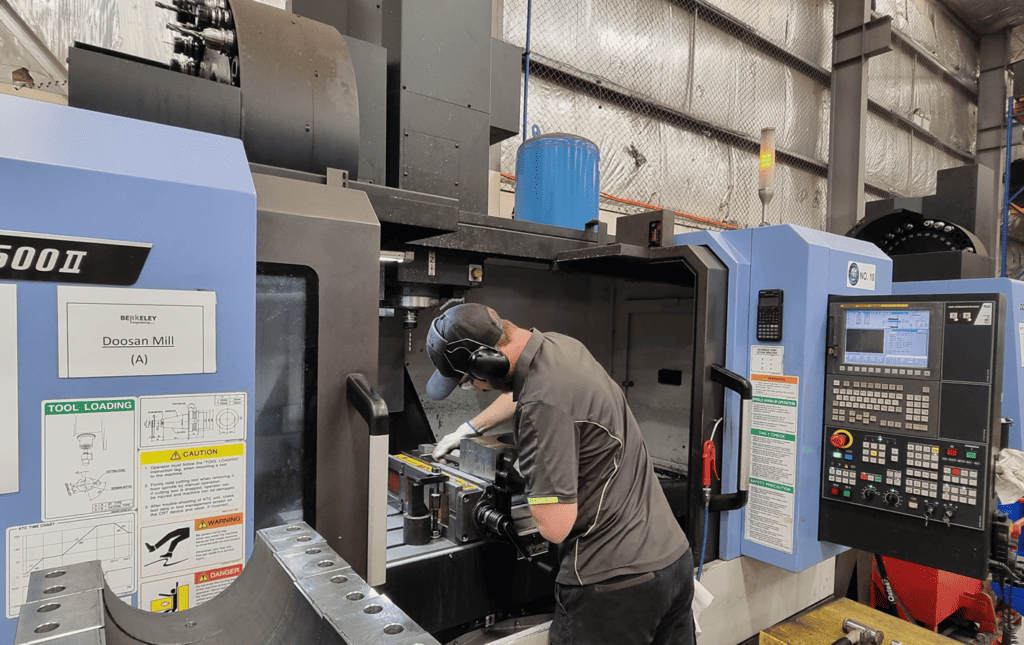

At Berkeley Engineering, we leverage advanced CNC machining technology to provide Australian mining operations with durable, high-quality components that withstand extreme conditions.

Applications of CNC Machining in Mining

1. Equipment Components

- Hydraulic cylinders

- Wear-resistant drill bits and cutting tools

- Structural components for conveyors and crushing equipment

2. Customised Replacement Parts

- Tailored to exact OEM specifications or improved for enhanced durability

- Fast production of critical replacement parts to minimise downtime

3. Protective and Structural Parts

- Heavy-duty casings and protective housings

- Structural brackets and reinforcement components

Materials Engineered for Tough Environments

Choosing the right material is crucial in mining applications. Berkeley Engineering offers CNC machining with robust materials designed specifically to endure Australia’s toughest mining environments, including:

- Stainless Steel: Superior corrosion resistance, ideal for wet and corrosive environments

- High-Strength Steel Alloys: Durable, impact-resistant parts for heavy mining equipment

- Aluminium: Lightweight yet robust, ideal for reducing equipment weight without compromising strength

- Wear-resistant Metals: Specialised alloys that reduce wear and prolong component life

The Berkeley Engineering Advantage – BE Assured of Excellence

Australian mining operations demand reliability. Berkeley Engineering has been trusted by the Australian industry for over 90 years. Our ISO 9001-certified CNC machining facility ensures every component is manufactured to strict quality standards, providing confidence and peace of mind. Clients choosing Berkeley Engineering can BE Assured of:

- Precision-engineered components delivered on time, every time

- Advanced machinery capable of handling complex, customised requirements

- Exceptional communication and a hassle-free partnership

- Robust quality control processes ensuring maximum reliability and performance

Real-World Success: Mining Equipment Case Studies

Increasing Equipment Durability

A leading Australian mining company approached Berkeley Engineering with a challenge: their equipment parts were frequently failing due to extreme environmental conditions. Using high-precision CNC machining and wear-resistant alloys, we produced customised components that significantly improved durability, extending component lifespan by over 30% and significantly reducing downtime.

Custom Part Replacement

When a mining operation urgently needed a critical replacement component, our CNC machining capability enabled rapid turnaround. We delivered parts accurately engineered to tight tolerances within days, significantly reducing operational downtime and cost.

FAQs Answered:

Q: What tolerances can Berkeley Engineering achieve with CNC machining?

A: We consistently deliver tolerances as tight as ±0.01mm—because in mining, near enough isn’t good enough. That level of accuracy means our components perform under pressure, every time.

Q: Which materials are best suited for harsh mining environments?

A: We work with wear-resistant alloys, high-strength steel, aluminium, and stainless steel—materials proven to handle the grit, corrosion, and impact of real mining conditions.

Q: How quickly can you deliver replacement parts?

A: Our standard turnaround is 7 to 14 days, but when equipment’s down, we know every hour counts. That’s why we offer priority machining services for urgent replacements.

Q: Does Berkeley Engineering offer customised machining services for mining?

A: Absolutely. We don’t do one-size-fits-all. Every mining site is different, and we tailor each part to your equipment, your environment, and your specs.

Q: Can CNC machining improve equipment lifespan in mining?

A: Yes. Precision-machined parts reduce wear and improve fit, meaning less vibration, fewer failures, and a longer life for your gear—even in the harshest terrain.

Q: What’s the benefit of local CNC machining for mining operations?

A: Local means faster turnaround, tighter quality control, and support you can call on. With Berkeley, you get expert CNC parts made here—on spec and on time.

Who are we?

Berkeley Engineering has a rich history of producing high-quality components since 1931. Our CNC machining operations in Australia offer a comprehensive range of services, including CNC turning, metal fabrication, plasma cutting and more. We are dedicated to delivering custom components of the finest quality for your projects. Whether you require low or high volume production, our manufacturing services are cost-effective and efficient, with turnaround times as fast as one business day.

Contact Us:

We'd love to discuss your next project and how our partnered solutions can scale with your business operating needs.