Building with Precision: CNC Machining for Construction Applications

Introduction

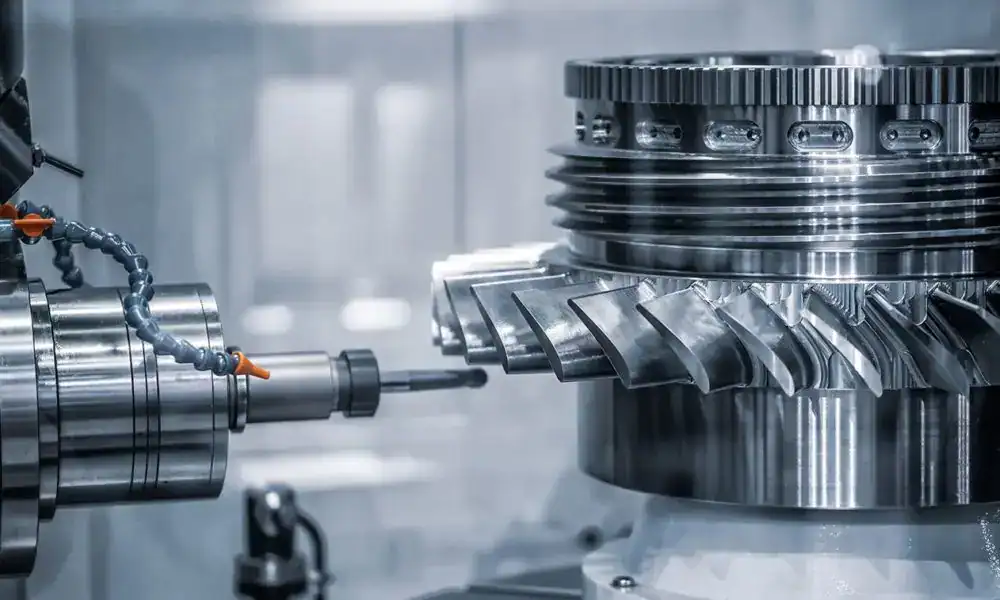

Precision is the backbone of modern construction. Whether it’s the structural framework of a high-rise, the intricate details of an architectural facade, or the functional components of an infrastructure project, every element must fit seamlessly and perform under extreme conditions. This is where CNC machining changes the game.

By leveraging computer-controlled precision machining, CNC technology ensures that construction components are manufactured with unmatched accuracy, durability, and efficiency. Traditional methods leave room for human error, material waste, and delays—CNC machining eliminates these inefficiencies, delivering perfectly machined parts that fit first time, every time.

From load-bearing steel beams to custom aluminium panels and high-performance structural joints, CNC machining allows engineers and architects to push the boundaries of what’s possible. It reduces labour costs, speeds up construction timelines, and enhances the overall quality of a build.

In this article, we’ll explore the impact of CNC machining on construction, the materials and techniques that set it apart, and how Berkeley Engineering delivers precision-engineered solutions that transform the way we build.

Key Takeaways

- CNC machining provides high-precision components for structural and architectural applications, ensuring a perfect fit in construction projects.

- Steel, aluminium, and composites are widely used in CNC-machined construction components for strength, longevity, and weather resistance.

- Advanced machining techniques like multi-axis milling, drilling, and cutting allow for the production of custom, high-performance building materials.

- CNC machining reduces material waste, lowers costs, and accelerates project timelines, making construction more efficient and cost-effective.

- Berkeley Engineering offers tailored CNC-machined solutions, built for structural strength, efficiency, and long-term reliability in modern construction.

Summary Table

| Feature | Impact on Construction |

| High Precision | Ensures seamless integration and flawless fits |

| Customisation & Complexity | Allows for unique, project-specific designs |

| Strength & Durability | Produces long-lasting, high-load components |

| Cost & Time Efficiency | Reduces waste, labour, and installation time |

| Scalability | Supports both custom projects and mass production |

The Role of CNC Machining in Construction

Construction is an industry where precision is non-negotiable. A single miscalculation in a support bracket or steel beam can result in structural misalignment, costly rework, and even safety risks. CNC machining eliminates these uncertainties by producing highly accurate, perfectly machined components that integrate seamlessly into construction assemblies.

Beyond accuracy, CNC machining also brings consistency at scale. Whether fabricating hundreds of identical connection plates or custom-machined brackets for a complex structure, CNC ensures repeatable precision across every unit. This is crucial for large-scale infrastructure projects, where standardised components must meet strict engineering tolerances.

CNC machining also allows for more complex and efficient designs. Engineers can create high-strength, lightweight components that would be impossible to fabricate with traditional methods. Whether it’s precision-cut steel for modular construction or custom decorative panels for a high-end commercial facade, CNC machining enables endless possibilities in modern building design.

Materials Used in CNC Machining for Construction

The choice of material in CNC machining determines the durability, resilience, and performance of construction components.

- Steel: The backbone of construction, CNC-machined steel is used in beams, reinforcements, and high-load structures. Its strength makes it ideal for skyscrapers, bridges, and industrial facilities.

- Aluminium: Valued for its lightweight properties and corrosion resistance, CNC-machined aluminium is used in facades, window frames, and roofing where strength is needed without adding excessive weight.

- Composite Materials: CNC machining allows the use of high-performance composites in prefabricated wall panels, ventilation systems, and architectural elements, offering durability with reduced structural load.

By selecting the right material for each project, CNC machining ensures that construction components withstand environmental conditions, structural stresses, and long-term wear, making them essential for high-performance buildings and infrastructure.

CNC Machining Techniques for Construction

To meet the demands of construction, CNC machining employs advanced fabrication techniques that provide precision, efficiency, and high-quality finishes.

- Multi-Axis Machining: Enables highly complex, precise cuts from multiple angles, allowing for the fabrication of custom brackets, reinforced steel joints, and curved architectural elements.

- Drilling & Cutting: Ensures accurate bolt holes, slots, and connection points in beams, plates, and support structures, allowing for easy assembly.

- Surface Finishing: Processes like powder coating, galvanising, and anodising protect CNC-machined components from corrosion, weather damage, and wear, ensuring long-term performance.

These machining techniques enable Berkeley Engineering to deliver flawless components that improve construction timelines and long-term durability.

Benefits of CNC Machining in Construction

- Unmatched Precision – Every component is machined to exact tolerances, eliminating human error and ensuring a perfect fit.

- Reduced Material Waste – CNC machining optimises material usage, minimising scrap and unnecessary costs.

- Faster Construction Timelines – Pre-machined components arrive ready for installation, significantly reducing on-site fabrication time.

- Scalability & Customisation – CNC machining accommodates both mass production and bespoke designs, offering flexibility for various project needs.

- Enhanced Durability – Components withstand heavy loads, extreme temperatures, and environmental exposure, making them ideal for long-lasting construction applications.

Applications of CNC Machining in Construction

CNC machining is widely used in structural, architectural, and infrastructure projects:

- Structural Components – Machined beams, brackets, and connection plates provide rigid, load-bearing frameworks for buildings and bridges.

- Architectural Features – Custom staircases, decorative facades, and precision-cut panels enhance both functionality and aesthetics.

- Infrastructure & Large-Scale Projects – CNC-machined parts ensure precision and strength in roadways, tunnels, and public infrastructure.

Its versatility makes CNC machining an indispensable part of modern construction, ensuring projects are built to the highest standards of accuracy, efficiency, and strength.

Conclusion

CNC machining has transformed construction by ensuring that every beam, bracket, and component is crafted with precision, efficiency, and long-term durability. By integrating CNC-machined parts into modern construction, architects, engineers, and builders can achieve greater accuracy, reduced costs, and faster project completion.

At Berkeley Engineering, we provide custom CNC solutions that meet the demands of high-performance construction projects. Be assured—our expertise delivers flawless results, every time.

Let’s build with precision. Contact us today to discuss your CNC machining needs.

Frequently Asked Questions

Q: How does CNC machining improve construction precision?

A: CNC machining eliminates human error by using computer-guided cutting, milling, and drilling, ensuring components meet exact specifications and fit perfectly into construction assemblies.

Q: What types of construction projects benefit from CNC machining?

A: CNC machining is used in high-rise buildings, bridges, commercial developments, and modular construction, where precision-engineered components are crucial.

Q: Why is CNC machining preferred over traditional fabrication methods?

A: It offers higher accuracy, faster production, and less material waste, resulting in cost savings and improved efficiency in large-scale construction.

Q: How does CNC machining contribute to sustainable building practices?

A: It minimises material waste, optimises energy efficiency, and enables the use of recyclable metals, reducing environmental impact.

Who are we?

Berkeley Engineering has a rich history of producing high-quality components since 1931. Our CNC machining operations in Australia offer a comprehensive range of services, including CNC turning, metal fabrication, plasma cutting and more. We are dedicated to delivering custom components of the finest quality for your projects. Whether you require low or high volume production, our manufacturing services are cost-effective and efficient, with turnaround times as fast as one business day.

Contact Us:

We'd love to discuss your next project and how our partnered solutions can scale with your business operating needs.